The last official project of the summer was a quick mod to my Lian Li PC-A05NB case. For those not familiar with the case, the PSU sits in the bottom front of the case. The case is designed with airflow from in the back to exiting from the front (reverse of all other cases). Before I upgraded to a Core i7, my Core 2 Duo system was experiencing some heat related issues due to exhaust issues through the front.

This mod began in late June when I went with a friend to the technical college he was taking a “How to create anything” class at. Using the mill in the classroom, I cut a hole in the front of the case (originally wanted to use the laser cutter, but it can’t cut through aluminum). It isn’t visible in the provided pictures, but the hole is slightly crooked, but most won’t notice it if I don’t point it out.

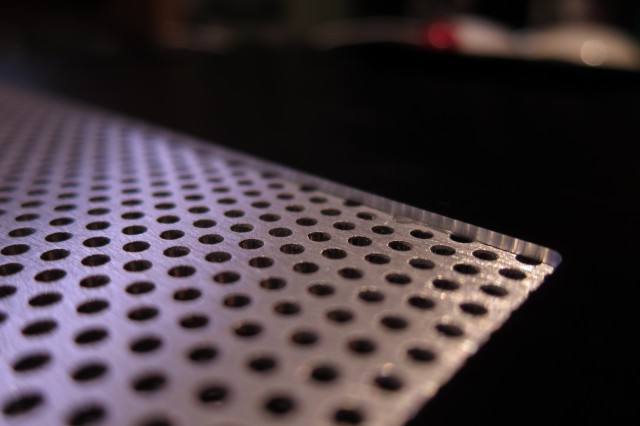

The front panel sat, hole cut, all summer. Last night, I finally took the time to cut out the perforated aluminum and mix up some epoxy to bond the “mesh” to the front panel. After 24 hours of curing, the front panel is done. Below are two pictures of the results.

-John Havlik

[end of transmission, stay tuned]

Very cool John! Where did you pick up the perforated aluminum?

My dad recently bought a mill and I am hoping to eventually do some fun projects on it. Your post may give me some inspiration to get started. :-)

Someone a few years back was selling the perforated aluminum on ebay (it was a metal shop out of Missouri if I remember correctly). If you have Amazon Prime, I’d suggest searching Amazon for perforated aluminum (free shipping FTW). Or, just talk to a local metal supply shop.

How large of a mill did he get? I always end up needing something larger than what we have (we have a smallish mill/lathe combo machine). The one I used for this project was really a CNC machine that we use in manual override mode. It was probably smaller than what we have, but I think the movable plane was larger in one of the directions. I still had to make have the cut with the front panel mounted in one position, then finish off the cut with a second mounting (pain in the butt).

-John Havlik

Thanks for the tip, I am a big Amazon Prime fan. :-)

It’s a Bridgeport mill, pretty good sized. Just sent a photo to your email…